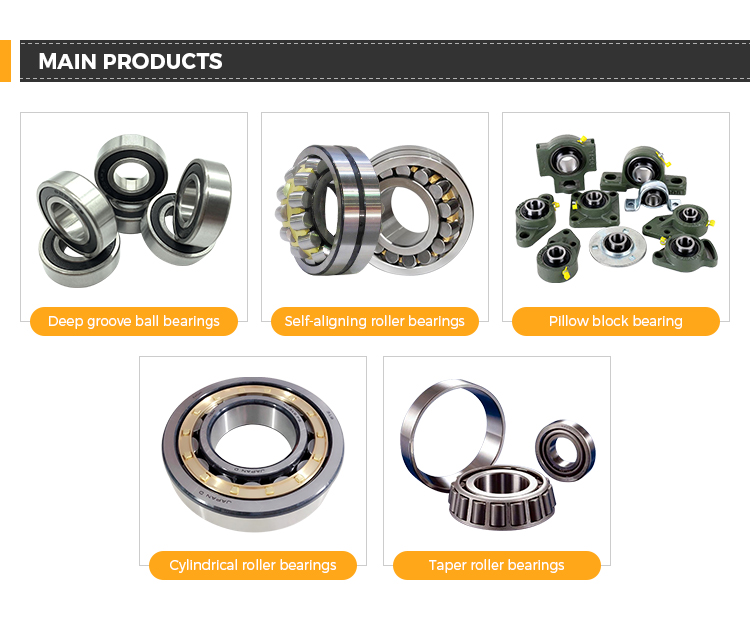

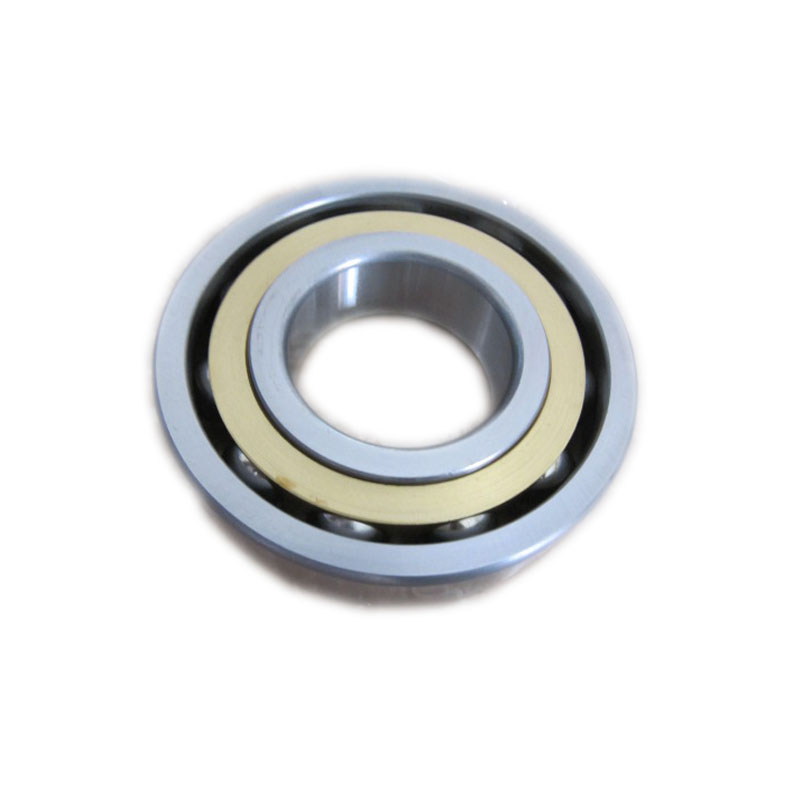

Single Row Ball Angular Contact Ball Bearings

Angular Contact Ball Bearing 7011C 55x90x18 Bearing

Angular contact ball bearings have raceways in the inner and outer rings that are displaced with respect to each other in the direction of the bearing axis, which means that they are designed to accommodate combined loads, i.e. simultaneously supporting radial and axial loads.The axial load carrying capacity of angular contact ball bearings increases with increasing contact angle. The contact angle α is defined as the angle between the line joining the points of contact of the ball and the raceways in the radial plane, along which the load is transmitted from one raceway to another, and a line perpendicular to the bearing axis.Retainers are made of brass ,synthetic resin of others subject to individual bearing features and application conditions.

Working principle:

It uses axially asymmetric races. An axial load passes in a straight line through the bearing, whereas a radial load takes an oblique path that tends to want to separate the races axially. So the angle of contact on the inner race is the same as that on the outer race. Angular contact bearings better support "combined loads" (loading in both the radial and axial directions) and the contact angle of the bearing should be matched to the relative proportions of each. The larger the contact angle (typically in the range 10 to 45 degrees), the higher the axial load supported, but the lower the radial load.

Types:

Angular contact ball bearings are produced in a wide variety of designs and sizes.Those commonly used and included in this catalogue are:

1.Single-row angular contact ball bearings

Axial load in single direction can be sustained. While supporting pure radial load, the bearings must be installed and used in pairs since the line of action of the rolling element load is not in the same plane as that of the radial one, resulting in inner separate force.

2.Double-row angular contact ball bearings

This is basically a back-to-back mounting of two single-row angular contact ball bearings, but their inner and outer rings are each integrated into one. Axial loads in both directions can be sustained, and the capacity to sustain moments is good. This type is used as fixed-end bearings. Their cages are pressed steel.

3.Four-point angular contact ball bearings

The inner ring is split radially into two pieces. Their design allows one bearing to sustain significant axial loads in either direction. The contact angle is 35°, so the axial load capacity is high. This type is suitable for carrying pure axial loads or combined loads where the axial loads are high. The cages are made of machined brass.

They are mainly used for steel industry,mining&construction,papermaking machinery, wind turbines,semiconductors,machine tools,gearboxes,electric motors,pumps&compressors,injection moldingmachines.